Asset Management

MM Survey offers solution for virtual asset management

Benefits

Your organisation will benefit by implementing Asset Management System

- Reduced cost by limiting site visits

- All documentation in one place

- Easy to use without training

- Direct link from As-built documentation to direct view

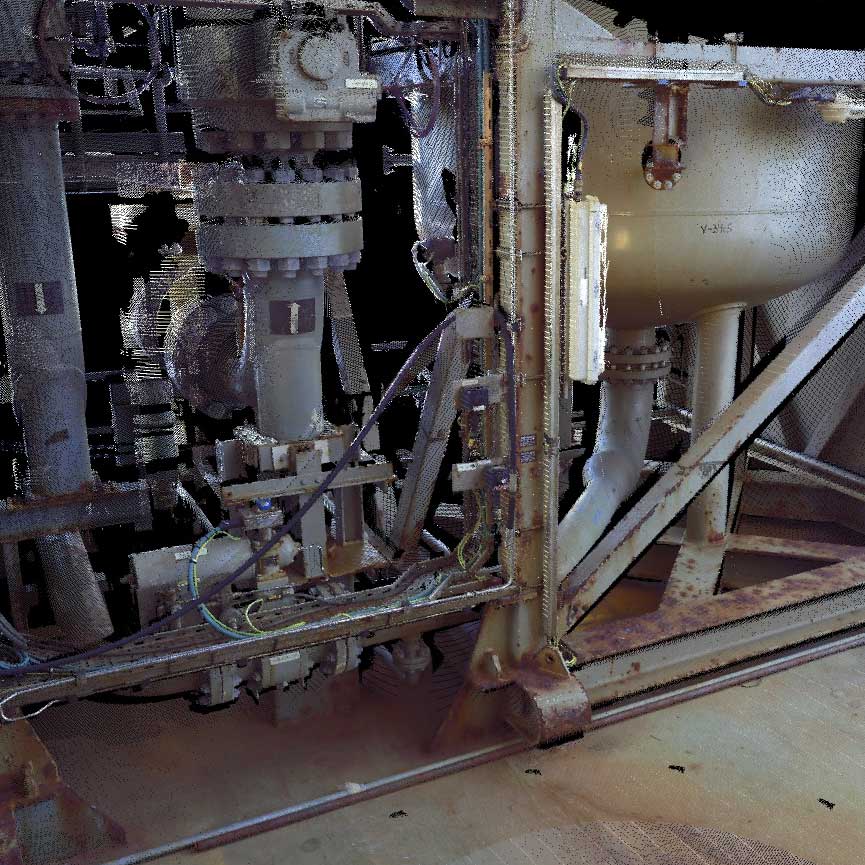

Photographic documentation of the asset will allow for quick site visit.

MM Survey has special experience and competencies in capturing and processing the data on the offshore and onshore installations.

Turn-key solution

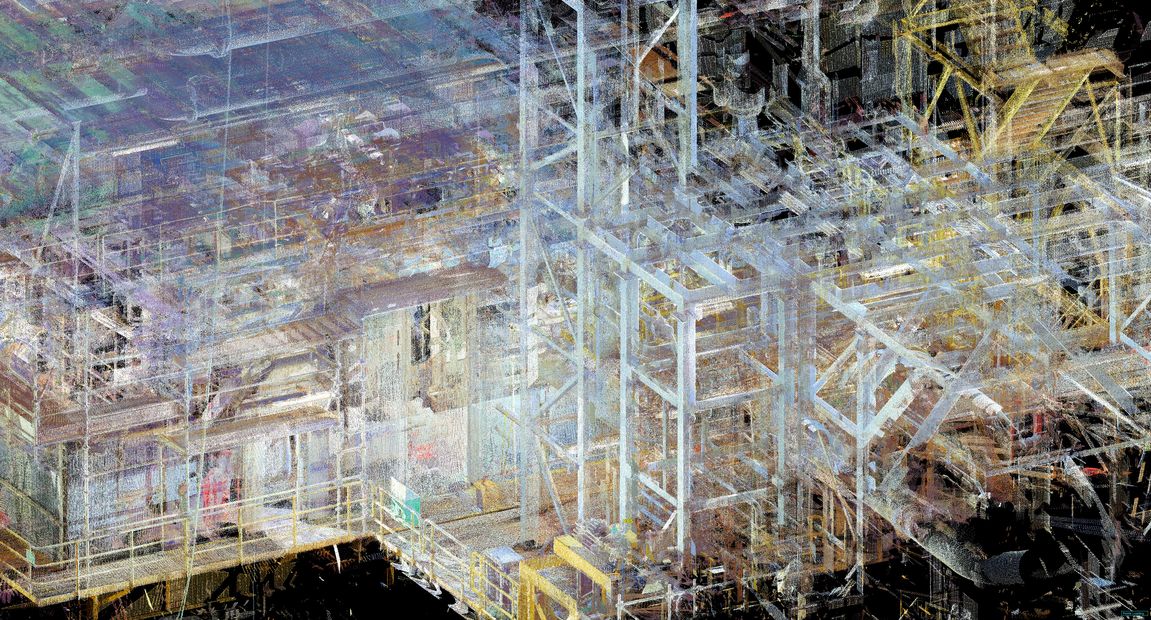

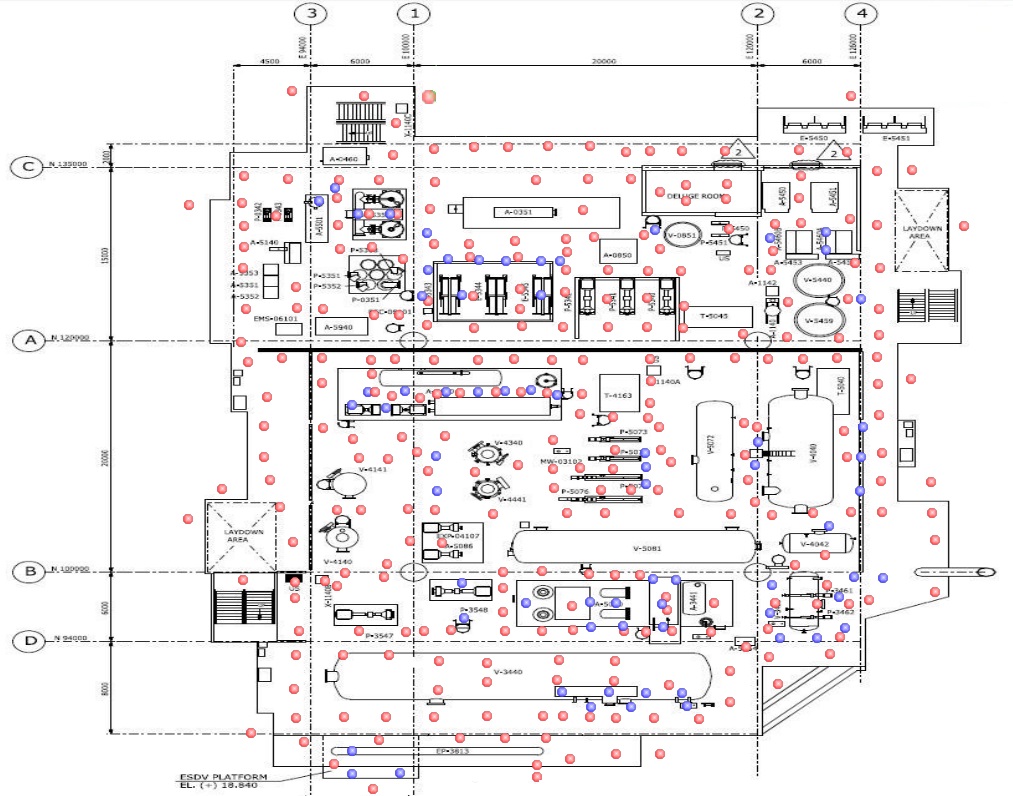

MM Survey delivers high quality 360° panoramic images linked together into walk through environment. Plan drawing of the facility is linked with the images to ease the navigation.

After successful deployment, end users can interact with the virtual world by uploading PDF documentation, images and text. This will allow to build a virtual environment with all documentation in place. MM Survey can assist by publishing the documentation on top of the virtual tour, but this process can be done as well by client personnel.

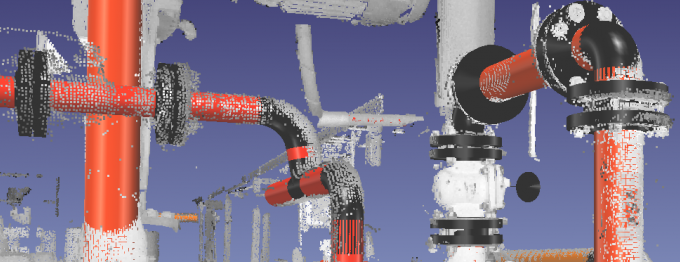

In order to reduce time used to search for the asset inside virtual environment, link from the design drawings like P&ID or PFD can be made. Our team will do a line walk to see it the piping fits to the design drawing and link each component with the view inside virtual tour. That way the owner of the facility and contractors will be able to find necessary information with no time.

End product can be deployed locally as a stand alone application or through the network. It will run on IE9 and above and other modern web browsers.

Asset Management System has proved to be a valuable resource in many aspects such as:

- Preparation of the projects

- Communication between departments

- FEED Studies

- Familiarisation and induction training